Printed a Magpul MOE wanna-be for my 468. Feels great. Print shifted up around the beaver tail, and I'm not really sure why, but I can't feel it, so I'm leaving it. PLA+ has been printing very well for me lately, and it's much less brittle than the carbon fiber PLA I was playing with before. It's so shiny though. I might experiment with high grit Emery cloth to dull it.

Announcement

Collapse

No announcement yet.

What did you 3D print today?

Collapse

X

-

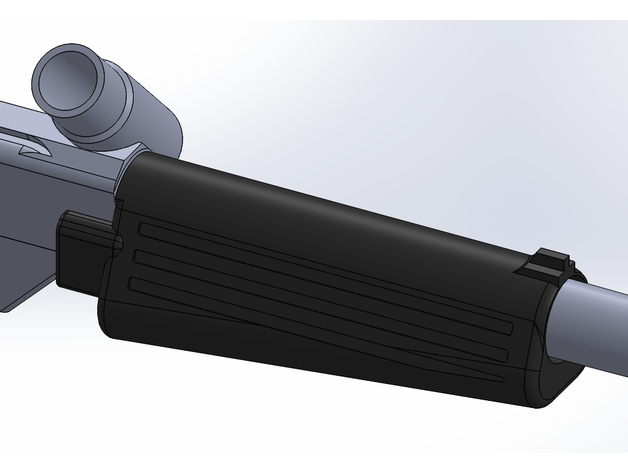

Finally got a part off my printer. Icd cat foregrip, not my design. It was on thingiverse. It makes a cat so comfy and can be used on other shooters like pro carbs.

it's not great, but I'll take it. Inland petg .2 layer height, no cooling. My duct kept snagging the print so I pulled the ducts and printed this. I think the lack of minor cooling caused the zitty over hangs, but they honestly add grip so it's no biggie. My friend made me the same handle on his creality K1. And it's much nicer.

Foregrip for any of the Indian Creek Design "Cat" paintball guns (Thunder Cat, Alley Cat, Bobcat, Puma). Modeled after the Tippmann “Pro” series foregrip (Pro/Carbine, Pro-Lite, Pro-Am, F/A). It clamps to the 1" OD section of the upper receiver. Requires 10-32 x 1/2" socket head cap screws and 10-32 nuts, 2 each. I suggest printing with a raft for bed adhesion. The clamp piece should be printed with a relatively high infill density. The foregrip can be done with a medium infill density.

Foregrip for any of the Indian Creek Design "Cat" paintball guns (Thunder Cat, Alley Cat, Bobcat, Puma). Modeled after the Tippmann “Pro” series foregrip (Pro/Carbine, Pro-Lite, Pro-Am, F/A). It clamps to the 1" OD section of the upper receiver. Requires 10-32 x 1/2" socket head cap screws and 10-32 nuts, 2 each. I suggest printing with a raft for bed adhesion. The clamp piece should be printed with a relatively high infill density. The foregrip can be done with a medium infill density.

Printing a new lower profile duct for my MAD now out of the same material. Hoping it doesn't clip prints. Then I'll print the clamp shoe for this grip.4 Photos

- Likes 3

Comment

-

This fit tight on my cat, and forcing it on cracked it to death... ugh,9 ours gone. I dunno what my issue is, but I'll spend speckled parts of my free time trying to get it working.

I'm about ready to scrap both of my printers and buy a more modern one. My buddy bought a creality K1, and he is printing 10x faster than me with 100x less issues out of the box. I've struggled to print anything at 30mm/s since day one, and I've tossed upgrades at these things the whole time.

-

Found a remixed duct for my aftermarket printer head assembly. It gives much more clearance from my print. Printing the clamping block for the above grip now with better part cooling.3 Photos

- Likes 1

Comment

-

- Likes 4

Comment

-

Honestly I am fantastically pleased with it. All of those pics are done with no name, chinesium/Amazon cheap filament. I have an FLSun V400, FLSun Super Racer, ender 3 V2, and Voxelab Aquila also. The FlSuns stock print really good… but the Bambu Lab A1 Mini still smokes them in quality. And it prints as fast as the V400. And the AMS Lite works great. And the full Mini/AMS combo was cheaper then I paid for the V400 on a lightning deal (it was $350 off!). My wife wasn’t interested I. Printing anything before. She is now interested and even sliced some stuff herself besides just printing directly from the Bambu App.

The best way I can describe this is like this; Bambu Lab put in the engineering time from fine tuning the machine with tech, including cost efficiency design, as well as ensuring the profiles are tuned to print great. And I mean that includes many different filament types, .2, .4, .6, .8 nozzle profiles, different beds, etc. The printing experience is wonderful. I haven’t been interested in the big Bambu machines because the beds aren’t big enough for what I want and I didn’t want to spend that much on what seemed like hype.

I understand the hype now. They are pumping out great machines and I can’t wait to see what else they do.

It isn’t perfect and still has the normal learning curves like dealing with bed adhesion… but this is dang close to a Cricut machine.

-

Finally. Spent some time tightening up bits on both printers.

The petg printer (left) had a loose gantry. And my retraction had defaulted to a bad setting. It has been so long, I didn't remember what it took to make this head work. .4mm at 5mm/s. Seems wrong, but it's a clean print so far. I'm printing a modified mozak phantom pump handle. I took the design MozakMachine has here on cult 3d, and I moved the pump arm hole to the center below the barrel. It should (maybe?? ) work on my new to me spitfire, and tippmann SL 68s.. maybe another phantom clone with a 10-32 under cocking pump rod... I totally eyeballed it as I had to draw on his mesh file.

link to his awesome work here. https://cults3d.com/en/3d-model/gadg...chine-products

Right printer had a dead cooling fan. Luckily I made that one plugged. So I swapped a new one out. I then put a new nozzle in. It was still printing like poo, so I put a new spool of filament into it that was dried to 30%. Printed a nice benchy with a little offset tuning and bumps of the bed springs.

Now I'm 9 hours into a 20 hour print. It looks good so far.....2 Photos

- Likes 2

Comment

-

Man, that pr6 does look nice.

As for my pump. The brass insert pushes it too far away from the barrel and it JUST binds at the end of the pump stroke. I might tire plug the hole, and model an m5 printed threaded hole and get it closer to the barrel. I am just making these in petg though. I wish I could churn asa out.

-

New pump handle printed with modled threads. Seems to work, but I'm not sure for how long. Haha.

This was started as I left for work, so I couldnt babysit and or tune so it's flawed. I'm convinced my petg is still wet after being cooked at 50c for days.

The wood pla stock my buddy printed for me. I intend on staining it.

These spitfire 2 guns are quickly growing on me.2 PhotosLast edited by BrickHaus; 11-20-2023, 09:01 PM.

- Likes 3

Comment

-

-

After 2 weeks of the ender being down for maintenance and trouble shooting, we're back. I put new wheels on all around as mine were definitely showing signs of wear. Also dropped a 0.4 nozzle back in so I could work on some Christmas prints for the wife.

Vase mode trees printed in transparent petg(god I love this stuff), going to get some led "candles" for these. The moose is from a snap card that we're going to be including with cards and gifts. Printed in PLA.Originally posted by Terry A. DavisGod said 640x480 16 color was a covenant like circumcision.

- Likes 3

Comment

-

- Likes 11

Comment

-

If you're intending on printing one out for yourself, I think I'm going to make one small tweak to improve tolerances a bit. It's pretty stable right now with only the slightest amount of side to side play (way less than a pump kit), but I think I can make it rock solid with one small change. The new file is up now labeled V2 in the filename.

-

Thankfully this one doesn't droop. Rather the tolerances in front of the rail allowed for the *slightest* bit of side to side play. Personally, I would probably be fine leaving it alone, but if others are going to start making them for their own Mags, then I wanted it to be perfect. Then again, perfectionist that I am, I probably would have ended up tweaking it anyway.

-

Ion XE blade trigger printed with Overture PLA+ @ .2mm layer height with a .4mm nozzle. Might re-do with regular PLA, as I understand that it would be stiffer and bend less. But as is, it's very usable with a mech conversion and I don't see it breaking any time soon.

(not my file)

Designed a trigger for the ION. Printed with a 0,25mm nozzle. Sized to fit the magnet from the original trigger. The trigger has no end screw but stops before it puts pressure on the controlboard. The no bearings trigger relies on the pin alone and SHOULD fit TheTrigger Version 6 has a bigger hole to pressfit three (3mm*6mm) bearings into it and sand down the original pin to 3mm diameter (or just use a 3mm Screw and a nut.)

Designed a trigger for the ION. Printed with a 0,25mm nozzle. Sized to fit the magnet from the original trigger. The trigger has no end screw but stops before it puts pressure on the controlboard. The no bearings trigger relies on the pin alone and SHOULD fit TheTrigger Version 6 has a bigger hole to pressfit three (3mm*6mm) bearings into it and sand down the original pin to 3mm diameter (or just use a 3mm Screw and a nut.)

- Likes 5

Comment

Comment